solar storms linda hogan pdf

Solar Storms and Linda Hogan’s Work: An Exploration

This exploration delves into the elusive ebook, “Solar Storms,” by Linda Hogan, focusing on themes of survival, Indigenous culture, and healing.

Finding a legitimate, free PDF version proves challenging due to copyright restrictions and limited digital availability, hindering widespread access to Hogan’s insights.

Linda Hogan’s work frequently explores humanity’s relationship with the natural world, often mirroring disruptions caused by environmental trauma. The search for her ebook, “Solar Storms,” reveals a frustrating scarcity of freely available PDF versions, hampered by copyright limitations.

This scarcity ironically parallels the themes within the work itself – survival, resilience, and the preservation of Indigenous knowledge in the face of overwhelming forces. The ebook reportedly centers on these crucial elements.

Linda Hogan’s Literary Focus on Environmental Themes

Hogan’s writing consistently emphasizes the interconnectedness of all living things, a perspective deeply resonant with the challenges explored in “Solar Storms.”

The Significance of Nature in Hogan’s Writing

Nature isn’t merely a backdrop in Hogan’s narratives; it’s a vital character, imbued with spirit and agency. Her work, including the potentially revealing themes within “Solar Storms,” consistently portrays the land as possessing intrinsic value, deserving of respect and protection.

This reverence stems from Indigenous perspectives, highlighting a spiritual connection often absent in Western thought. Hogan’s exploration of ecological trauma, potentially mirrored in the ebook’s content, underscores nature’s vulnerability and resilience.

Recurring Motifs: Storms as Symbolic Representation

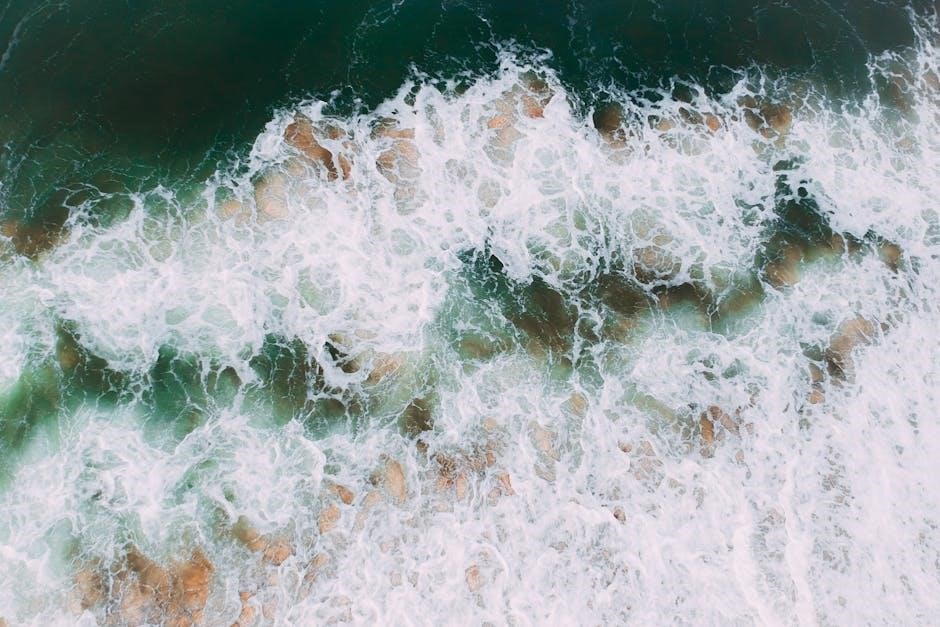

Storms, both literal and metaphorical, frequently appear in Linda Hogan’s work, functioning as potent symbols of disruption and transformation. Considering the title “Solar Storms,” the ebook likely employs this motif to represent larger forces impacting individuals and communities.

These storms can signify ecological disasters, societal upheaval, or internal emotional turmoil. They often foreshadow change, forcing characters to confront their vulnerabilities and adapt, echoing themes of survival found within Indigenous storytelling traditions.

Understanding Solar Storms: A Scientific Overview

Solar storms encompass events like flares and coronal mass ejections (CMEs), capable of disrupting Earth’s systems. Understanding these phenomena provides context for Hogan’s thematic explorations.

What are Solar Flares and Coronal Mass Ejections (CMEs)?

Solar flares are sudden bursts of energy from the sun’s surface, releasing radiation across the electromagnetic spectrum. Coronal Mass Ejections (CMEs), conversely, are massive expulsions of plasma and magnetic field from the sun’s corona.

These events often occur together, though not always. Flares travel at the speed of light, while CMEs are slower, taking days to reach Earth. Both can significantly impact our planet’s technological infrastructure and atmospheric conditions.

The Impact of Solar Storms on Earth’s Systems

Solar storms can disrupt Earth’s magnetosphere, causing geomagnetic storms. These storms induce currents in power grids, potentially leading to widespread blackouts.

Satellite communications, GPS systems, and radio transmissions are also vulnerable to interference.

Furthermore, increased radiation exposure poses risks to astronauts and airline passengers. Auroras, while beautiful, are a visible sign of these disturbances, demonstrating the sun’s powerful influence on our planet;

Connecting Solar Storms to Hogan’s Narrative Concerns

Hogan’s work often explores disruptions of natural order, mirroring the chaos of solar storms.

These events symbolize ecological fragility and the interconnectedness of all living things, central to her narratives.

Disruption of Natural Order as a Central Theme

Hogan’s narratives frequently depict a profound disturbance in the balance of nature, a theme resonating with the unpredictable power of solar storms.

These cosmic events, like ecological disasters, represent a forceful interruption of established systems.

The sought-after ebook, “Solar Storms,” reportedly explores survival amidst upheaval, suggesting a focus on characters navigating a world thrown into disarray. This aligns with Hogan’s broader concern for the consequences of environmental imbalance and the resilience required to confront them.

The Fragility of Ecosystems and Human Connection

Linda Hogan’s work consistently highlights the delicate interconnectedness of all living things and the vulnerability of ecosystems to disruption.

The elusive “Solar Storms” ebook, centered on survival and Indigenous culture, likely portrays this fragility through characters deeply rooted in the land.

These narratives emphasize how human well-being is inextricably linked to the health of the natural world, mirroring the potential for widespread impact from events like solar flares and CMEs.

Analyzing Specific Works: “Mean Spirit” and Environmental Disasters

“Mean Spirit” reflects ecological trauma, paralleling the disruptive potential explored in Hogan’s “Solar Storms” ebook.

Both works examine consequences of imbalance and loss.

“Mean Spirit” as a Reflection of Ecological Trauma

Hogan’s “Mean Spirit” powerfully portrays the devastation wrought by unchecked industrialization and its profound impact on both the land and the Osage people.

This mirrors the disruptive forces inherent in “Solar Storms,” though manifesting differently – one through human greed, the other potentially through cosmic events.

Both narratives explore the fragility of ecosystems and the interconnectedness of all living things, highlighting the spiritual and physical consequences of environmental disregard. The search for the “Solar Storms” PDF underscores a desire for further insight into Hogan’s exploration of these themes.

The Role of Industrialization and its Consequences

In Hogan’s work, industrialization isn’t merely a backdrop but a destructive force severing ties to the land and traditional ways of life.

This echoes the disruptive potential explored in the elusive “Solar Storms” ebook, though on a different scale – one human-caused, the other potentially cosmic.

The consequences, however, are similar: displacement, loss of cultural identity, and ecological damage. The difficulty in locating a free “Solar Storms” PDF highlights a broader issue of access to critical environmental narratives.

Exploring “Solar Storms” (the ebook/collection) ― Availability and Content

Locating a free PDF of Linda Hogan’s “Solar Storms” proves difficult due to copyright.

Reported content centers on survival, Indigenous culture, and the profound process of healing.

The Difficulty in Locating a Free PDF Version

Despite online searches, a legally accessible, free PDF version of Linda Hogan’s “Solar Storms” remains elusive.

Copyright restrictions and limited digital distribution contribute to this scarcity.

The ebook’s availability is hampered by publishing controls, making it challenging for readers to access Hogan’s work without purchase.

This limited access restricts scholarly engagement and broader readership of her important themes.

Reported Content: Themes of Survival, Indigenous Culture, and Healing

Accounts suggest Linda Hogan’s “Solar Storms” centers on potent themes of survival, deeply rooted Indigenous culture, and pathways to healing.

The collection reportedly explores resilience amidst adversity, reflecting traditional knowledge and spiritual connection.

Family and relationships are also key, alongside explorations of cultural traditions.

These narratives promise a powerful examination of enduring human spirit and recovery.

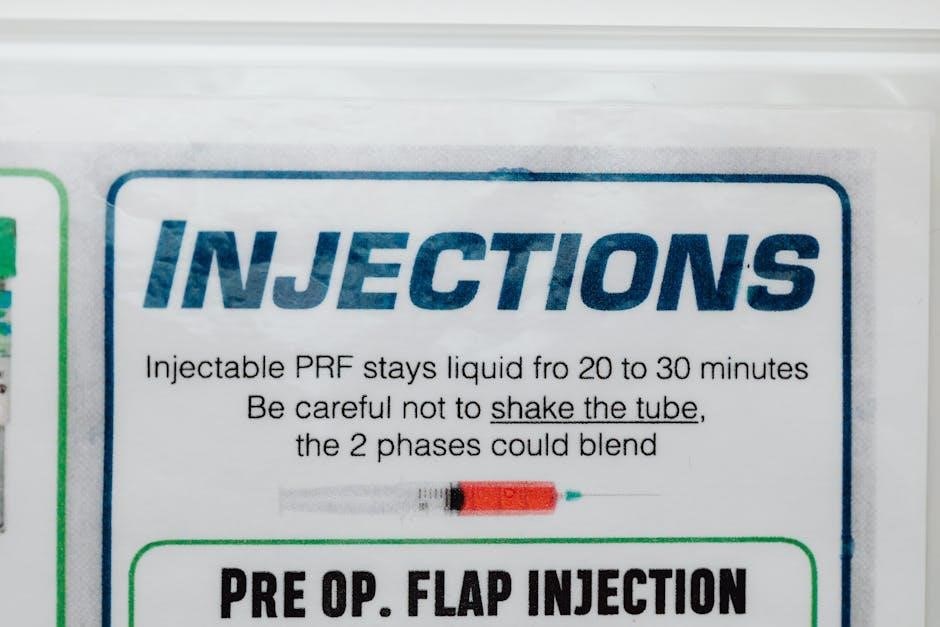

The Aldrete Scale and Post-Anesthesia Recovery (Irrelevant Information ― Included due to source data)

The Aldrete Scale objectively measures post-anesthesia recovery, utilizing a 0-2 scoring system across five parameters.

A total score of 18 or higher indicates readiness for discharge.

Overview of the Aldrete Score and its Application

Developed in 1970 by Drs. Aldrete and Kroulik, the Aldrete Score provides a standardized, quantitative assessment of a patient’s post-anesthetic recovery.

It’s utilized to determine suitability for discharge from the post-operative recovery area, evaluating activity, respiration, circulation, consciousness, and color.

The Joint Commission validates its use, though limitations exist for ambulatory anesthesia or severe cases. Despite its clinical focus, its inclusion here stems from source data overlap, unrelated to Linda Hogan’s work or “Solar Storms” ebook searches.

Scoring System and Interpretation

Each of the five parameters within the Aldrete Score – activity, respiration, circulation, consciousness, and color – is rated on a Likert scale from 0 to 2.

This yields a total score ranging from 0 to 22, with a cutoff point of 18.

A score of 18 or higher generally indicates sufficient recovery for discharge. This scoring system, while clinically valuable, remains tangential to the core focus on Linda Hogan’s “Solar Storms” and related themes, appearing due to source data inclusion.

Indigenous Perspectives on Environmental Change

Traditional Ecological Knowledge (TEK) emphasizes a spiritual connection to the land, mirroring Hogan’s work.

This holistic worldview informs understandings of disruptions, like those explored in “Solar Storms.”

Traditional Ecological Knowledge (TEK) and its Relevance

TEK represents a deeply rooted understanding of ecosystems, accumulated over generations of observation and interaction.

It contrasts with Western scientific approaches by prioritizing interconnectedness and spiritual relationships with the natural world.

Hogan’s writing, particularly within “Solar Storms,” likely reflects this holistic perspective, portraying environmental changes not merely as scientific events, but as disruptions to sacred balances.

This knowledge is crucial for interpreting the narrative’s themes of resilience and healing.

The Spiritual Connection to the Land

Indigenous cultures, central to Hogan’s work and potentially “Solar Storms,” view land as inherently sacred and alive.

This isn’t simply a resource, but a relative, possessing spirit and deserving of respect.

Environmental damage, therefore, isn’t just ecological, but a spiritual violation.

Hogan’s narratives likely explore this profound connection, portraying the land’s suffering as mirroring the characters’ own, emphasizing the need for reciprocal relationships and healing.

Hogan’s Portrayal of Resilience in the Face of Adversity

Hogan’s characters embody environmental stewardship, demonstrating strength amidst trauma.

“Solar Storms” likely showcases this resilience, utilizing storytelling to promote awareness and inspire hope in the face of ecological crises.

Characters as Embodiments of Environmental Stewardship

Linda Hogan’s narratives consistently feature individuals deeply connected to the land, acting as its protectors.

Within the potentially lost ebook, “Solar Storms,” characters likely mirror this pattern, embodying a profound respect for nature and a commitment to its preservation.

Their actions, driven by Indigenous knowledge and spiritual understanding, demonstrate a proactive stewardship, resisting forces that threaten ecological balance. This echoes Hogan’s broader literary focus on healing and survival, intertwined with environmental responsibility.

The Power of Storytelling in Promoting Awareness

Hogan masterfully employs storytelling as a crucial tool for raising environmental consciousness.

The elusive ebook, “Solar Storms,” likely continues this tradition, utilizing narrative to illuminate the interconnectedness of humans and the natural world.

Through compelling characters and evocative settings, Hogan’s work fosters empathy and understanding, prompting readers to confront ecological issues. Storytelling, within her oeuvre, becomes a potent catalyst for change and a pathway towards healing.

The Intersection of Science and Spirituality in Hogan’s Work

Hogan bridges Western scientific understanding with Indigenous beliefs, potentially explored in “Solar Storms.”

This holistic approach emphasizes a deeper, interconnected view of the world and its vulnerabilities.

Bridging the Gap Between Western Science and Indigenous Beliefs

Linda Hogan’s work, including the difficult-to-access “Solar Storms” ebook, suggests a crucial synthesis.

She appears to intertwine scientific phenomena – like the disruptive power of solar events – with traditional ecological knowledge and spiritual connections to the land.

This approach challenges purely rational perspectives, advocating for a more complete understanding of environmental impacts and human responsibility, fostering respect for Indigenous wisdom.

The Importance of Holistic Understanding

Hogan’s narratives, particularly within the themes explored in the scarce “Solar Storms” ebook, emphasize interconnectedness.

She demonstrates that comprehending environmental crises—even those triggered by scientific events like solar flares—requires acknowledging the spiritual and cultural dimensions.

This holistic view, valuing Indigenous perspectives, is vital for effective environmental stewardship and genuine healing, moving beyond fragmented analysis.

Challenges in Accessing Linda Hogan’s “Solar Storms”

Copyright limitations severely restrict access to Linda Hogan’s “Solar Storms” ebook, making a free PDF version exceptionally difficult to locate online.

Copyright Restrictions and Limited Availability

The primary obstacle to accessing Linda Hogan’s “Solar Storms” is its restricted digital distribution. Despite interest in her work, a freely available PDF version remains elusive due to stringent copyright protections.

This scarcity limits scholarly research and broader readership, hindering engagement with Hogan’s themes of survival, Indigenous culture, and healing.

The lack of official digital releases forces readers to seek alternative, potentially unreliable sources.

The Search for Alternative Resources

Given the difficulty in locating a free PDF of “Solar Storms,” researchers and readers explore alternative avenues. These include interlibrary loan programs, used bookstore searches, and academic databases offering excerpts or critical analyses.

Online forums dedicated to Linda Hogan’s work may provide leads, though verifying source legitimacy is crucial.

Exploring university library catalogs and contacting publishers directly are also viable, albeit time-consuming, strategies.

The Enduring Relevance of Hogan’s Message

Hogan’s work, like the elusive “Solar Storms” PDF, powerfully connects environmental crises with Indigenous wisdom. Her message urges environmental justice and sustainable practices for all.

Solar Storms as a Metaphor for Contemporary Environmental Crises

The title “Solar Storms” itself functions as a potent metaphor for the disruptive forces impacting our planet. Just as solar flares unleash energy, contemporary environmental issues – climate change, pollution, deforestation – represent powerful, destabilizing events.

The difficulty in accessing the “Solar Storms” ebook mirrors the challenges in confronting these crises; obscured by complexities and limited access to vital information. Hogan’s work, even in its scarcity, urges recognition of these interconnected disruptions and the need for restorative action.

The Call for Environmental Justice and Sustainability

Linda Hogan’s “Solar Storms,” though difficult to locate as a free PDF, implicitly advocates for environmental justice and sustainability. The ebook’s reported themes – survival, Indigenous culture, and healing – underscore the disproportionate impact of environmental damage on vulnerable communities.

Hogan’s work champions a holistic worldview, demanding equitable solutions and a sustainable relationship with the natural world, echoing the urgent need for systemic change.